Annotate

Train

Automate

aivisiontrainer.com

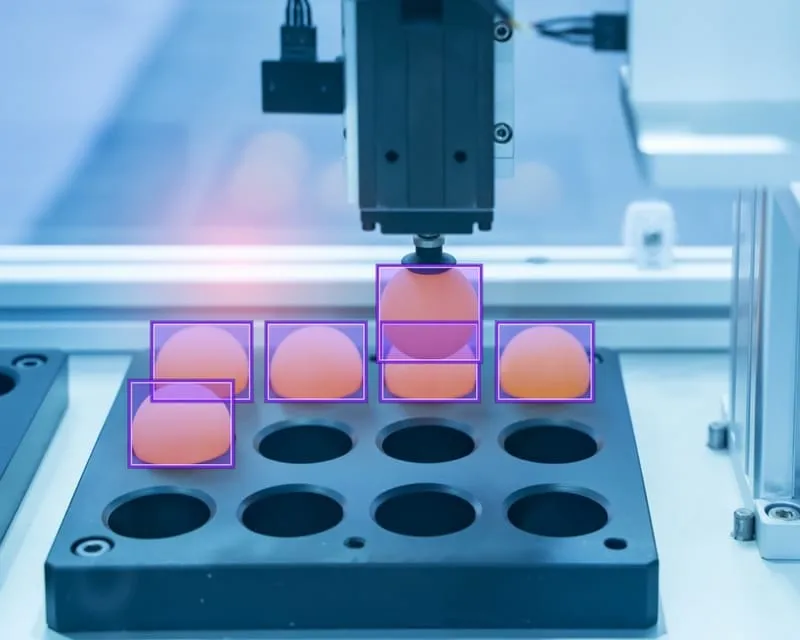

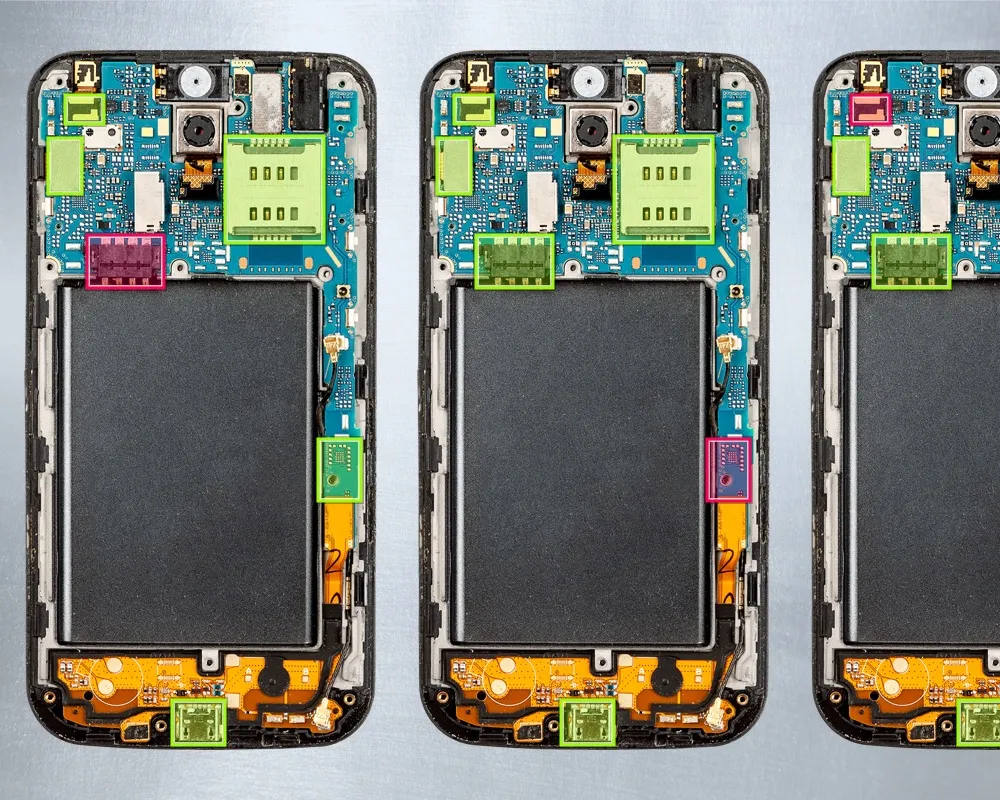

Defect Detection and Quality Control

Object detection AI revolutionizes manufacturing by automating defect detection and quality control processes. These systems analyze visual data from production lines to identify defects, such as scratches, dents, or irregularities, in manufactured products. By detecting defects in real-time, manufacturers can ensure product quality, reduce waste, and minimize rework, leading to improved efficiency and customer satisfaction.

Equipment Monitoring and Predictive Maintenance

Object detection AI enhances manufacturing by monitoring equipment and machinery to enable predictive maintenance. These systems analyze visual data to detect anomalies and signs of wear and tear in machines, enabling early detection of potential failures. By predicting maintenance needs, manufacturers can reduce downtime, extend equipment lifespan, and optimize maintenance schedules, improving productivity and reducing costs.

Production Line Optimization

Object detection AI optimizes manufacturing production lines by analyzing visual data to identify bottlenecks and inefficiencies. These systems monitor production processes in real-time, detecting anomalies and deviations from optimal performance. By identifying areas for improvement, manufacturers can streamline workflows, increase throughput, and reduce cycle times, leading to enhanced productivity and competitiveness.

Workplace Safety and Hazard Detection

Object detection AI improves workplace safety in the manufacturing industry by monitoring environments to detect hazards and ensure compliance with safety regulations. These systems analyze visual data to identify safety hazards, such as blocked emergency exits or unauthorized personnel in restricted areas. By detecting hazards in real-time, manufacturers can prevent accidents, reduce injuries, and create safer working environments for employees.

your project into a success story.